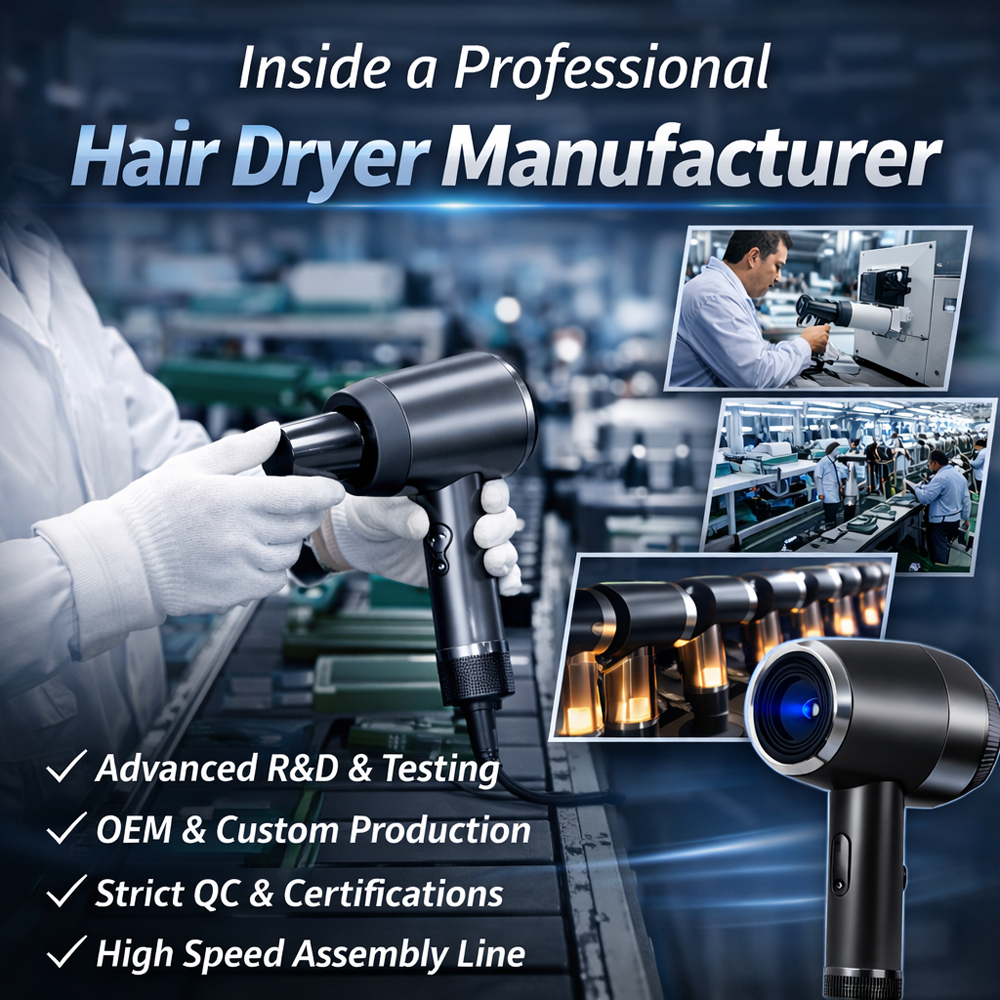

Inside a Professional Hair Dryer Manufacturer

2026-01-19

What Happens Inside a Professional Hair Dryer Factory?

When global brands and distributors look for a reliable hair dryer factory, they are not only searching for products — they are searching for manufacturing capability, quality control, and long-term partnership.

Inside a professional hair dryer manufacturer, every detail matters: from R&D and motor testing to automated assembly lines and international certifications. This article takes you inside a modern hair dryer factory, revealing how professional hair dryers are designed, manufactured, tested, and delivered for global markets.

1. Professional Hair Dryer Manufacturing Overview

A professional hair dryer factory operates as an integrated manufacturing system. At Teejoin, hair dryer production covers:

Industrial-scale hair dryer manufacturing

Dedicated high speed hair dryer production lines

OEM / ODM customization capability

Strict compliance with CE, ISO, and global safety standards

From raw material sourcing to final inspection, each production step follows standardized operating procedures to ensure stable quality and consistent output.

2. Hair Dryer R&D and Engineering Capabilities

A premium hair dryer manufacturer begins with strong R&D.在·

Key R&D capabilities include:

High-speed brushless motor development

Airflow and noise optimization

Heat control and temperature balance testing

Smart appliance electronics integration

Prototype development and validation

As a smart appliance factory, Teejoin continuously improves motor efficiency, airflow speed, and energy consumption to meet the expectations of professional salons and premium consumer brands.

3. Hair Dryer Production Line & Assembly Process

Inside the hair dryer production line, manufacturing is divided into specialized stations:

Motor installation and balancing

Heating element assembly

PCB and electronic control integration

Housing and structure assembly

Cable, plug, and safety component installation

This modular assembly process allows the factory to efficiently support:

OEM hair dryer factory orders

Private label hair dryer manufacturing

Custom housing, logo, and packaging solutions

4. Quality Control & Hair Dryer Testing Process

Quality control is the core of any professional hair dryer factory.

Each hair dryer undergoes multiple inspections, including:

Hair dryer motor testing (speed, torque, durability)

Temperature and overheating protection tests

Noise level testing

Airflow and wind speed verification

Electrical safety and insulation testing

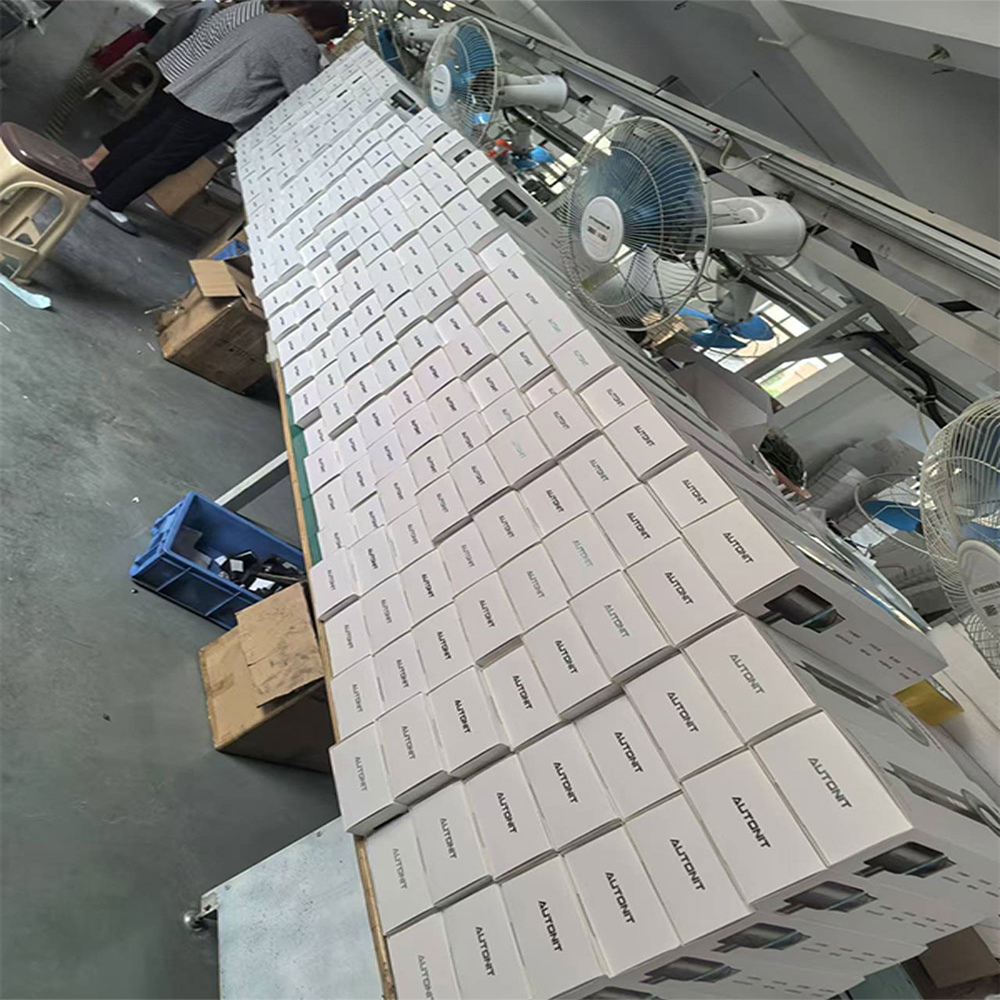

Only products that pass full hair dryer QC inspection proceed to packaging. This ensures consistent quality for international customers and compliance with CE-certified hair dryer factory standards.

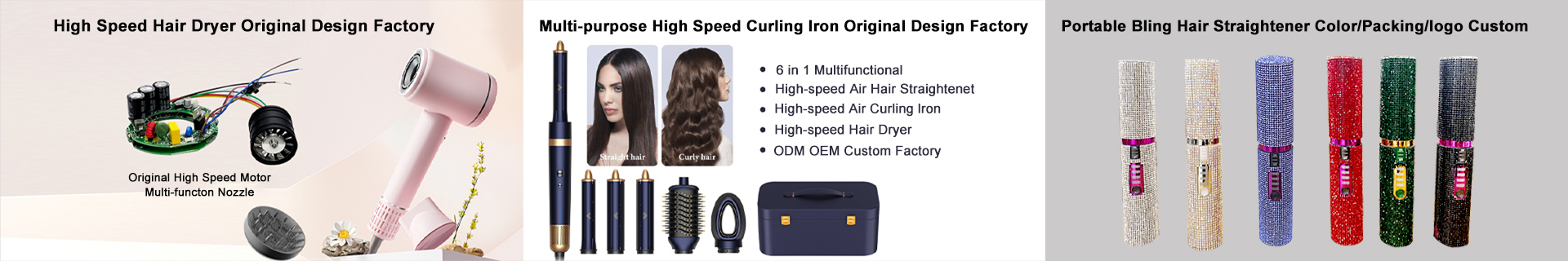

5. OEM, ODM & Custom Hair Dryer Manufacturing

As an experienced custom hair dryer manufacturer, Teejoin supports full OEM and ODM services:

Custom motor configurations

Housing design and color options

Branding, logo printing, and private labeling

Packaging design for different markets

Voltage and plug customization for EU / US / UK

This flexibility allows brands to launch differentiated products while relying on a stable hair dryer supplier in China.

6. Certifications & Global Compliance

A trusted professional hair dryer manufacturer must meet international compliance requirements.

Factory and products are certified with:

ISO factory management systems

CE certification for EU markets

Electrical and safety compliance standards

RoHS and environmental requirements

These certifications ensure that products manufactured can be legally sold and safely used across global markets.

7. Why Choose a Professional Hair Dryer Manufacturer?

Working directly with a high speed hair dryer factory offers key advantages:

Lower production costs without quality compromise

Faster customization and product iteration

Direct communication with engineers and production teams

Stable supply chain and scalable production capacity

For brands seeking long-term growth, partnering with a premium hair dryer manufacturer ensures consistent quality, innovation, and market competitiveness.

Conclusion: Your Trusted Hair Dryer Manufacturing Partner

Inside a professional hair dryer factory, quality, innovation, and precision come together.

As an experienced hair dryer manufacturer, Teejoin provides:

Advanced hair dryer manufacturing

Reliable production and testing systems

OEM / ODM customization support

Global certification compliance

Whether you are sourcing a high speed hair dryer, launching a private label brand, or expanding your product line, partnering with a professional manufacturer ensures your success.

☆ Contact Teejoin to explore custom hair dryer manufacturing solutions.