Quality Control Checklist for OEM Hair Dryers | Hair Dryer QC Guide

A Practical Guide to Hair Dryer QC, Inspection & Compliance

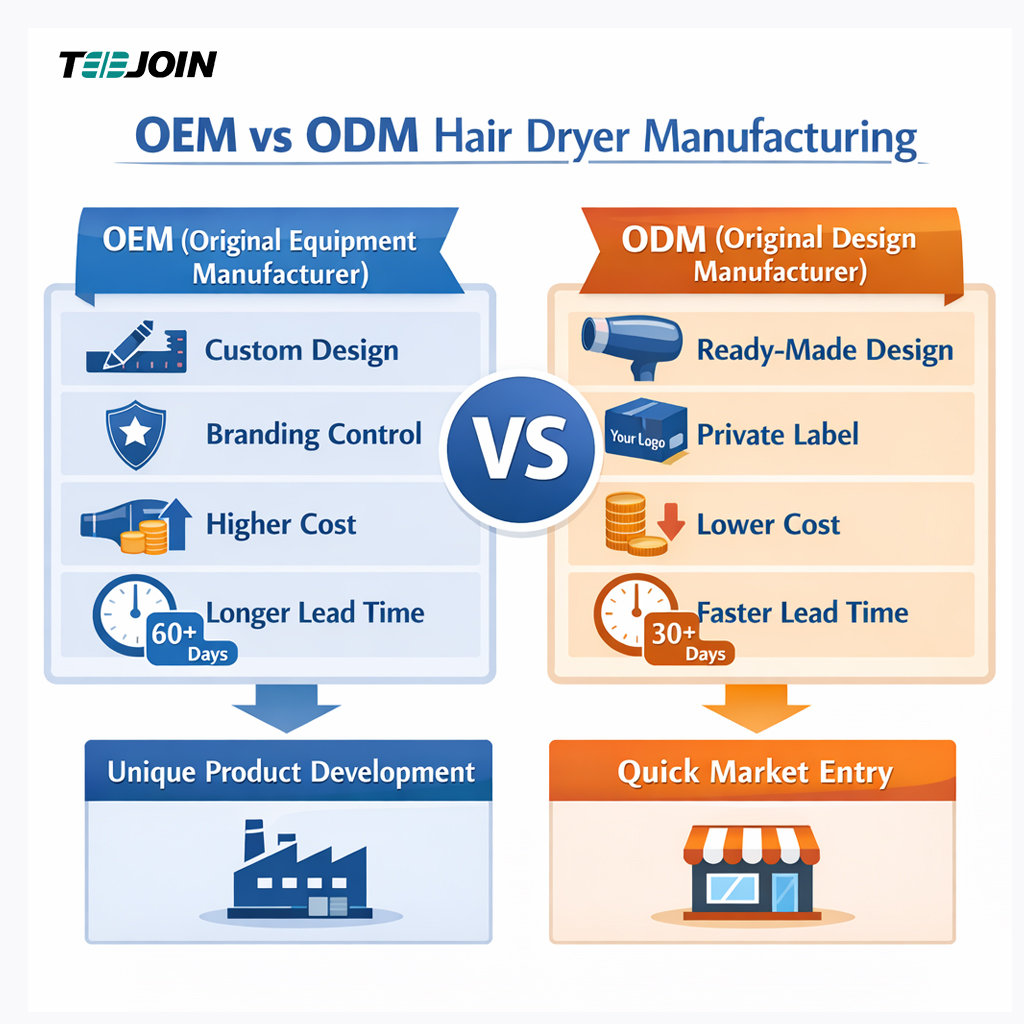

When sourcing OEM hair dryers, quality control is not optional — it is the foundation of brand reputation, customer safety, and long-term business success. For distributors, private label brands, and retailers in Europe and North America, a clear hair dryer QC checklist helps ensure every unit meets performance, safety, and regulatory expectations.

This guide walks you through a professional OEM hair dryer quality control process, covering inspection points, testing standards, factory audits, and compliance requirements used by reliable manufacturers.

Why Hair Dryer Quality Control Matters for OEM Buyers

In the beauty appliance industry, even small defects can lead to returns, negative reviews, or regulatory risks. A structured OEM supplier quality control system helps prevent:

Overheating or electrical safety issues

Motor failure and short product lifespan

Excessive noise or vibration

Inconsistent airflow and temperature

Non-compliance with CE, FCC, or other standards

A strong hair dryer manufacturing quality system protects both the brand owner and end users.

OEM Hair Dryer Quality Control Checklist (Step by Step)

1. Incoming Material Inspection

(IQC – Incoming Quality Control)

Before production begins, all key components must be inspected.

Inspection checklist includes:

Motor RPM and balance check

Heating wire material and resistance test

Power cord thickness and plug specification

Plastic housing (ABS/PC) heat resistance

PCB and electronic components verification

This step is critical for early hair dryer defect control.

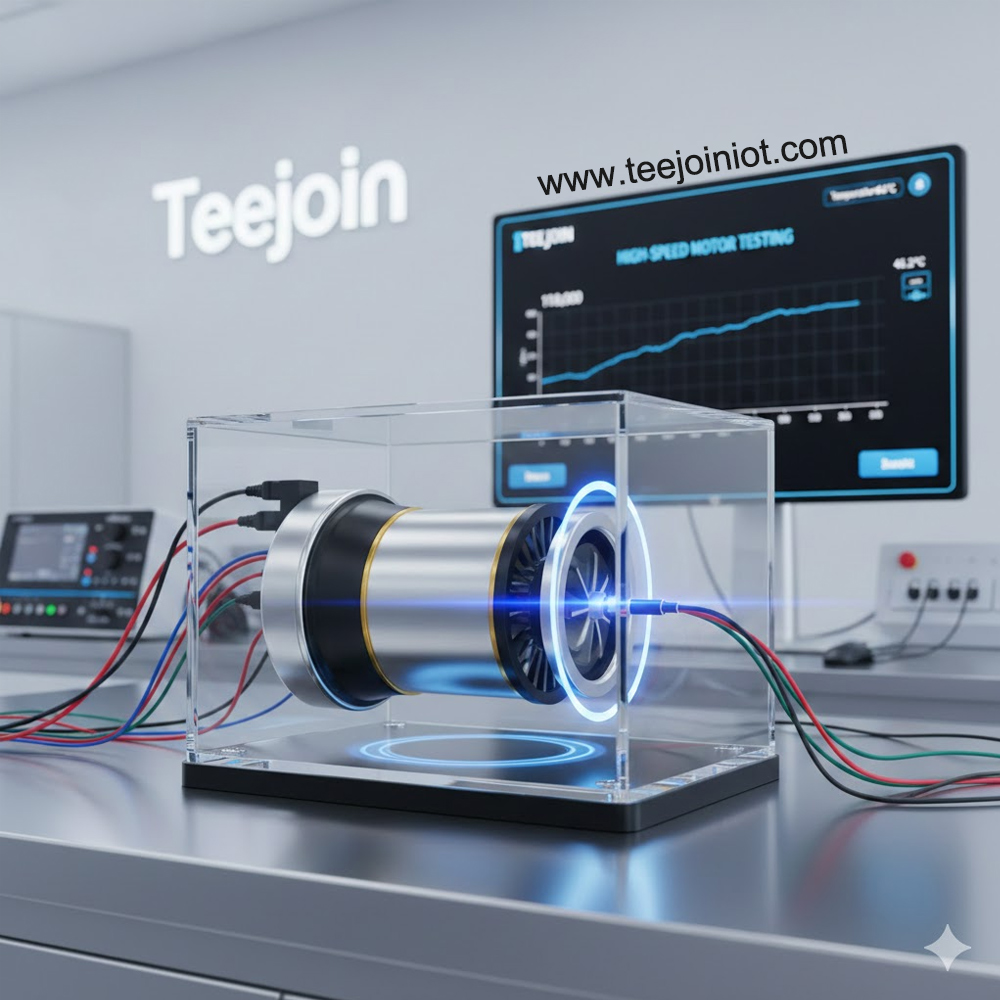

Illustration showing motor, heating wire, PCB, and housing being checked at the factory entrance.

2. In-Process Quality Control

(IPQC – During Production)

During assembly, QC teams monitor consistency and workmanship.

Key inspection points:

Wiring layout and insulation protection

Screw torque and assembly alignment

Heating element installation accuracy

Fan blade clearance and balance

Internal airflow channel sealing

Effective IPQC reduces rework and ensures stable production quality checklist execution.

Step-by-step visual of inspection during motor assembly, wiring, and housing closure.

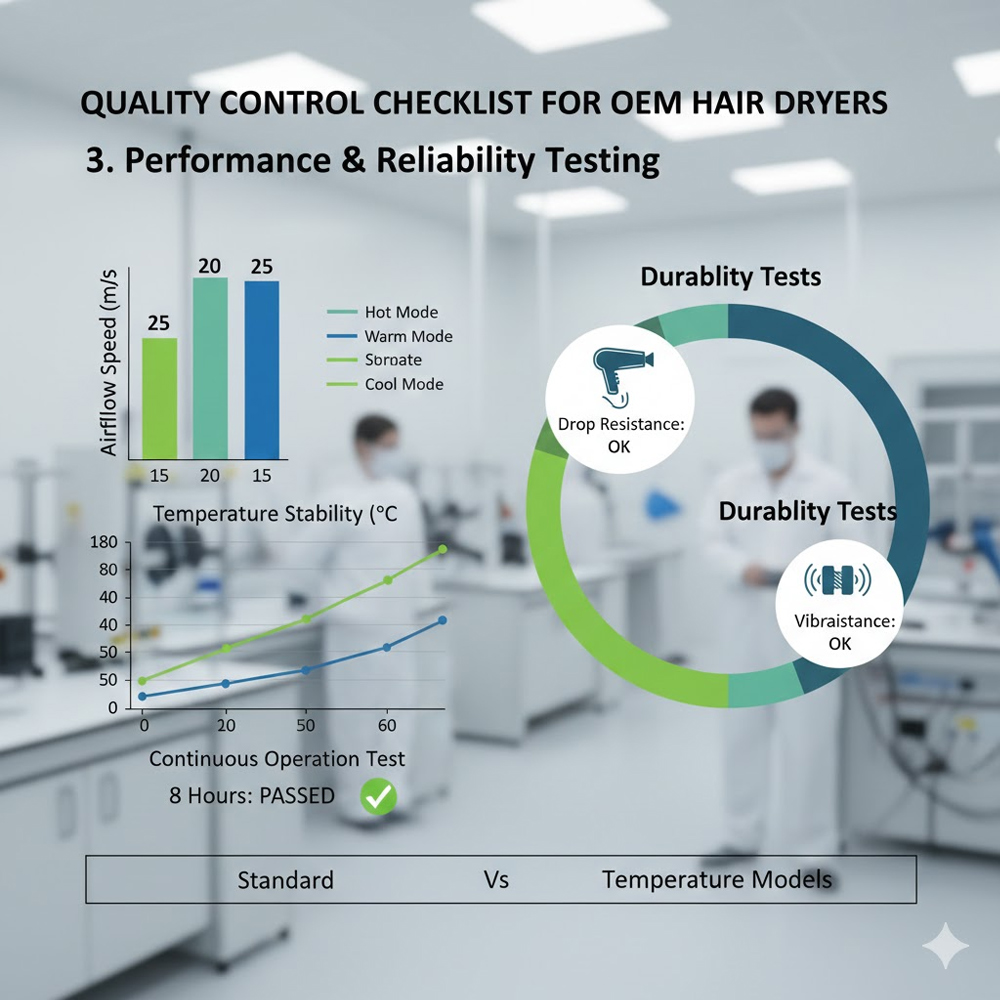

3. Performance & Reliability Testing

Every OEM hair dryer should undergo standardized functional testing.

Hair dryer testing standards typically include:

Airflow speed (m/s) and volume

Temperature stability (hot/warm/cool modes)

Power consumption and voltage tolerance

Continuous operation test (4–8 hours)

Drop and vibration resistance testing

This stage focuses on hair dryer reliability testing, especially important for high-speed and brushless motor models.

Comparison chart showing airflow, temperature control, and durability test results.

4. Safety Inspection & Compliance Testing

For EU and US markets, hair dryer safety inspection is non-negotiable.

Mandatory checks include:

Insulation resistance test

Leakage current test

Grounding continuity test

Overheat protection verification

Fire resistance of materials

Most OEM buyers also require third-party lab testing for:

CE (LVD + EMC)

FCC

RoHS / REACH

Lab setup showing electrical safety and thermal protection tests.

5. Final Inspection Before Shipment

(FQC – Final Quality Control)

Before packing, finished products are inspected based on AQL standards.

Final checklist includes:

Appearance (scratches, color consistency)

Logo and labeling accuracy

Function test of each unit

Packaging integrity (drop test)

User manual and compliance marking verification

This step ensures the OEM hair dryer meets customer expectations at delivery.

QC staff checking appearance, packaging, and labeling before shipment.

Factory Audit: Evaluating OEM Supplier Quality Control

A reliable hair dryer factory audit goes beyond product checks.

Audit focus areas:

QC process documentation (IQC / IPQC / FQC)

Testing equipment calibration records

Production traceability system

Worker training and SOP compliance

Corrective & preventive action (CAPA) system

Professional OEM factories welcome audits — it shows transparency and confidence.

Common Defects Prevented by a Strong QC System

An effective beauty appliance QC system significantly reduces:

Motor imbalance and noise issues

Heating inconsistency

Power cord breakage

Loose internal wiring

Cosmetic defects and poor finishing

For OEM brands, fewer defects mean fewer returns and stronger market trust.

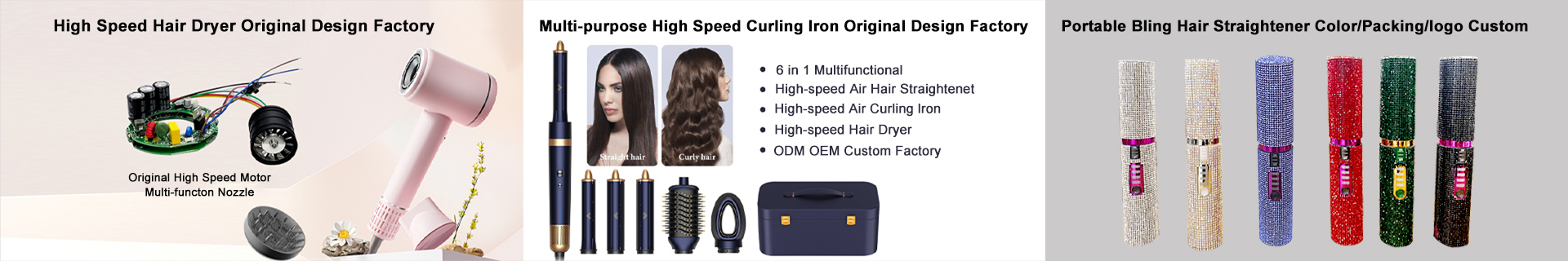

How Teejoin Implements OEM Hair Dryer Quality Control

At Teejoin, quality control is integrated into every production stage.

Dedicated QC team for hair dryer inspection process

In-house testing labs for performance and safety

Compliance-ready production for CE, FCC, and global markets

OEM hair dryer QC checklist customized per client requirement

Our goal is simple: stable quality, reliable performance, and long-term OEM partnerships.

Conclusion

A clear Quality Control Checklist for OEM Hair Dryers is essential for any brand sourcing from factories. From material inspection to compliance testing, each step protects product quality and brand reputation.

If you are looking for an OEM partner with a proven hair dryer quality control system, choosing a factory with transparent inspection standards and documented testing processes makes all the difference.