Brushless Motor vs Traditional Motor Hair Dryers

2026-01-10

What Is a Brushless Motor Hair Dryer and How Does It Work?

A brushless motor hair dryer is a new generation of professional hair drying technology designed to deliver higher airflow, faster drying speed, lower noise, and longer lifespan compared to traditional motor hair dryers.

As global demand grows for energy-efficient, durable, and smart beauty appliances, brushless motor technology has become the core of modern professional salon hair dryers and premium consumer hair dryers.

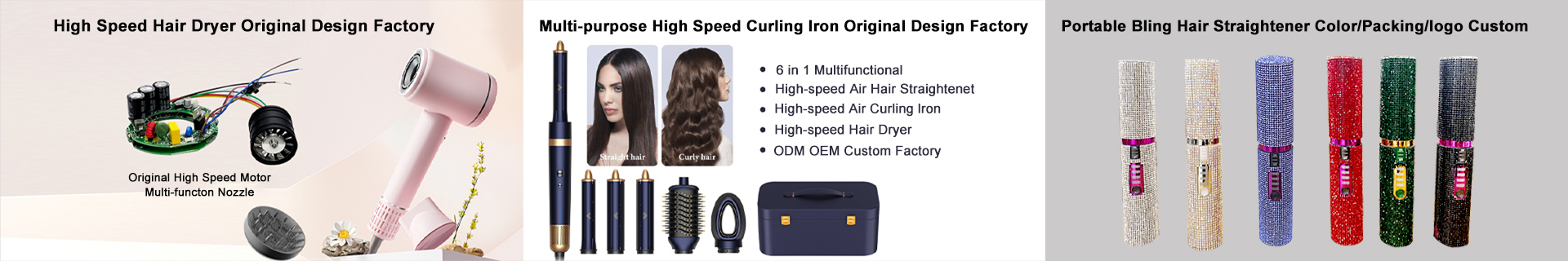

As a high speed hair dryer and hair styling tools factory in China, Teejoin Technology specializes in OEM hair dryer motor solutions for international brands, salon equipment suppliers, and distributors.

What Is a Brushless Motor Hair Dryer?

A brushless motor hair dryer uses a digital motor without carbon brushes, unlike traditional AC motor hair dryers that rely on physical contact brushes to generate rotation.

This design allows the motor to:

Spin at extremely high speed (up to 110,000 RPM)

Deliver consistent high torque

Reduce mechanical friction and heat buildup

Extend hair dryer lifespan significantly

Because of these advantages, digital motor hair dryers are widely used in commercial hair dryers, salon equipment, and premium beauty appliances.

How Does a Brushless Motor Hair Dryer Work?

A brushless motor hair dryer works through electronic motor control rather than physical brushes.

Key Working Principles:

Electronic control board regulates motor speed

High-speed rotation generates powerful airflow

Smart motor control adjusts output based on heat and airflow demand

Reduced energy loss improves efficiency and durability

Brushless Motor vs Traditional Motor Hair Dryers

Understanding the hair dryer motor comparison helps buyers and brands make better decisions.

| Feature | Brushless Motor Hair Dryer | Traditional Motor Hair Dryer |

|---|---|---|

| Motor Type | Digital brushless motor | AC motor with carbon brushes |

| RPM | Up to 110,000 RPM | 15,000–20,000 RPM |

| Noise Level | Low noise operation | Loud |

| Energy Efficiency | High | Low |

| Motor Lifespan | Long-lasting | Shorter |

| Overheating Risk | Low | Higher |

This is why brushless vs AC motor technology is now standard in professional salon hair dryers.

Why 110,000 RPM Matters in Hair Dryer Performance

The hair dryer RPM directly affects airflow strength and drying speed.

A 110,000 RPM high torque motor provides:

Faster water evaporation

Reduced heat exposure

Shorter drying time

Improved styling control

This enables a fast drying hair dryer experience without excessive heat, helping to prevent hair dryer overheating and hair damage.

Low Noise, High Efficiency & Durability

Because brushless motors have fewer moving parts, they offer:

Low noise motor hair dryer performance

Reduced vibration

Improved hair dryer durability

Lower maintenance requirements

This makes them ideal for:

Commercial hair dryers

Salon equipment suppliers

Long-hour professional use

Smart Motor Control & Hair Dryer Technology

Modern brushless motor hair dryers integrate smart motor control systems, which:

Monitor temperature in real time

Prevent overheating

Balance airflow and heat automatically

Extend product lifespan

This technology reflects the future of hair dryer manufacturing and beauty appliance innovation.

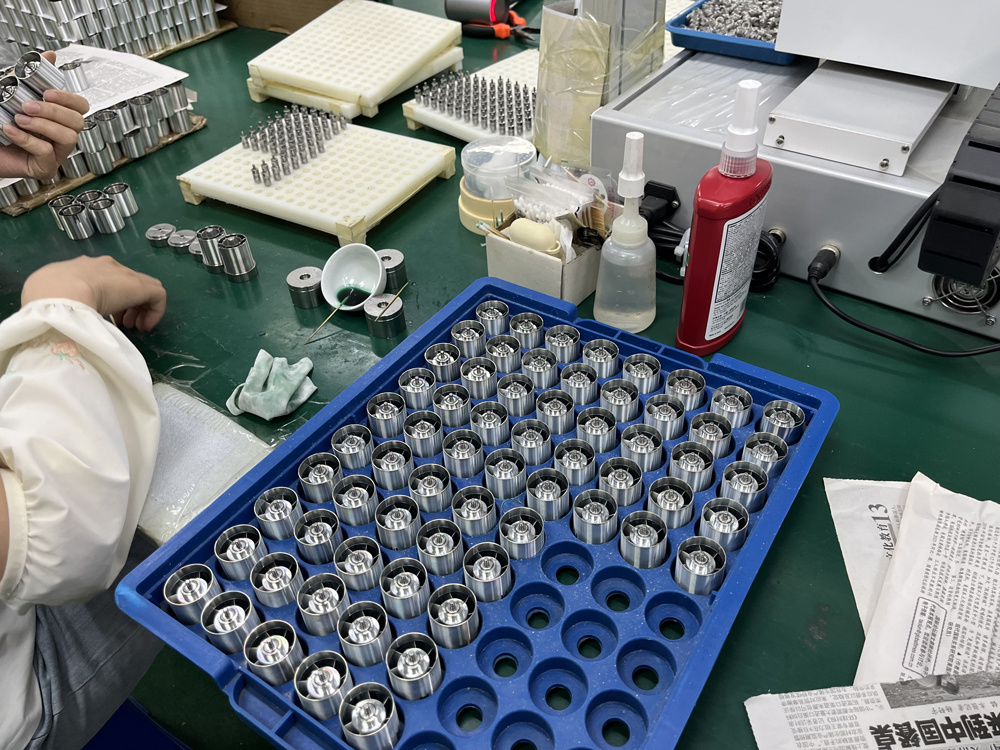

OEM Brushless Motor Hair Dryer Manufacturing in China

As a professional hair dryer factory in China, Teejoin Technology provides:

Custom brushless motor hair dryer solutions

OEM & ODM development

Motor tuning for different markets

Compliance with CE, FCC, RoHS

Stable supply for global brands

We support custom hair dryer motor design, housing customization, and private label production for premium and commercial markets.

Conclusion

A brushless motor hair dryer represents a major leap in hair dryer technology, delivering superior performance, durability, and efficiency compared to traditional motor hair dryers.

For brands, salons, and distributors seeking premium, professional, and long-lasting hair dryer solutions, brushless motor technology is no longer optional—it is the industry standard.